A sustainable and reliable hydrogen economy for Hesse

Hydrogen is a versatile energy carrier and a real alternative to fossil fuels in terms of energy transition and climate protection. Studies assume a market ramp-up of water electrolysis, in Germany alone, between 50 and 80 GW in the power grid by 2050. Hydrogen produced in a climate-friendly way makes it possible to reduce CO2 emissions, especially in industry and transport, where energy efficiency and the direct use of electricity from renewable energies are not sufficient. Hydrogen and its other synthesis products thus play a central role in achieving greenhouse gas neutrality in all energy-consuming sectors, such as transport, industry and buildings.

Reducing the specific demand for critical materials

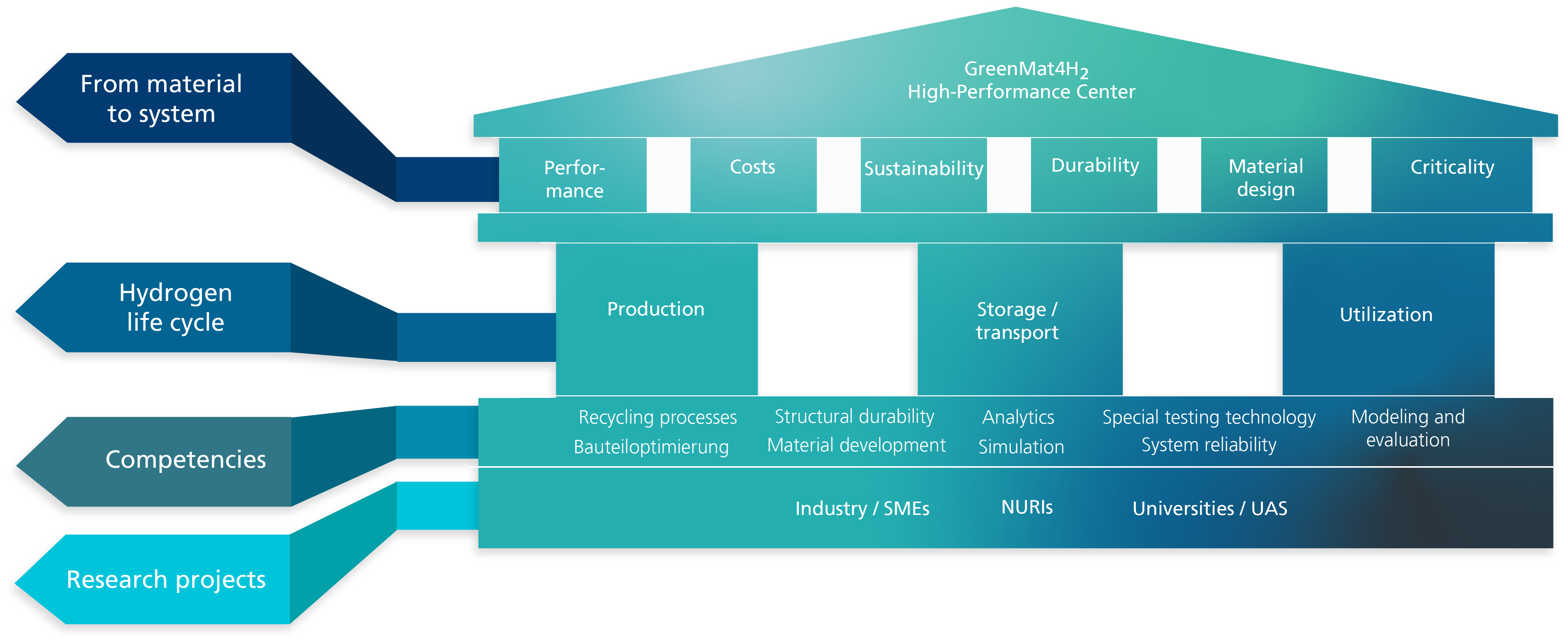

The research work of the Fraunhofer Institutes at the Hydrogen Performance Center Hesse always follows the principle of a holistic approach. If one analyses the life cycle of hydrogen, with a view to actual sustainability, from production to storage/transport to use, multiple requirements arise in diverse areas. Various critical materials are bound up in the material components that are used throughout the hydrogen cycle, which significantly reduce the carbon footprint in the production of green hydrogen. This is precisely where the research work of the performance center comes in.

Durability and safety

How can hydrogen be used for mobile applications in transportation? Can existing infrastructures be used for this purpose? What challenges does this pose for hydrogen-loaded materials and systems in terms of reliability and service life? These questions are addressed by the research work of the Fraunhofer LBF. Using individually developed test and validation methods and infrastructure, the influences of hydrogen under realistic stresses on the fatigue of materials, parts and components are determined and optimized service life estimates are derived from them.

The opportunity: a holistic approach

Throughout the entire cycle, all processes are put to the test in terms of their actual sustainability and longevity. The evaluation of the material criticality of, for example, fuel cells and their components and alternatives to fuel cells are also part of the research.

The aim of the research work is to develop a circular economy for all material components and entire systems for greater sustainability in the field of green hydrogen.

High Performance Center - Green Materials for Hydrogen, Hesse

High Performance Center - Green Materials for Hydrogen, Hesse