Lifetime estimates for fuel cell systems

A major application scenario for hydrogen is its use in fuel cells to operate vehicles for both passenger and freight transport. The loads and stresses on fuel cells and their periphery, as well as the resulting service life of the components, have not yet been adequately investigated in many cases. One focus of the work at the performance center is therefore to determine the relevant data and use them to carry out service life estimates for fuel cell systems.

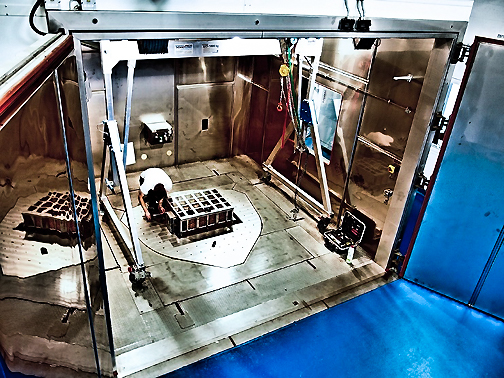

For this purpose, the scientists at Fraunhofer LBF have access to a comprehensive measurement, testing and validation infrastructure. Combining modeling and simulation with experimental methods of fatigue strength and reliability assessment, Fraunhofer LBF scientists at the performance center develop solutions for near-operational, multiphysical (thermal, electrical and mechanical) validation of the service life of, for example, fuel cell-battery systems for mobility applications.

In addition to corrosion investigations, environmental simulations and reliability evaluations, the research work includes the analysis of aging effects and oxidation phenomena and their effects on the service life and efficiency of the overall system, taking into account operating influences and real stresses during operation.

Based on the competences for the assessment of safety and reliability of electrical/electronic systems, scientists develop solutions for the quantitative reliability assessment of fuel cells. For this purpose, probabilistic and quantitative representation of cause-effect relationships (FMEA) is used to determine failure probabilities and safety figures. In addition, researchers at the Fraunhofer LBF are investigating wear and failure mechanisms of components and systems in the environment of hydrogen applications (e.g. drive components or high-pressure tanks) on the basis of material parameters under cyclic loading, in combination with other methods such as the acoustic emission method.

High Performance Center - Green Materials for Hydrogen, Hesse

High Performance Center - Green Materials for Hydrogen, Hesse