Numerous components and systems are in use, or have yet to be brought into use, for the production, transport and use of hydrogen. In order to make the hydrogen economy as efficient as possible, these hydrogen-carrying systems must also be designed efficiently and provided with a high power density.

Based on decades of experience in the field of component and system optimization, the Fraunhofer LBF offers numerous methods and approaches for this purpose in order to optimize application- and use-specific components, for example in the drive train of commercial vehicles, with regard to service life, safety and stressability. On the one hand, the approaches to fatigue strength, system reliability assessment as well as analytics and simulation methods pursued within the scope of the performance center serve to increase the safety of hydrogen-loaded components and systems. On the other hand, however, the findings also offer considerable potential for optimizing individual components through to entire structures with regard to their durability and reliability, but also with regard to approaches for material innovations.

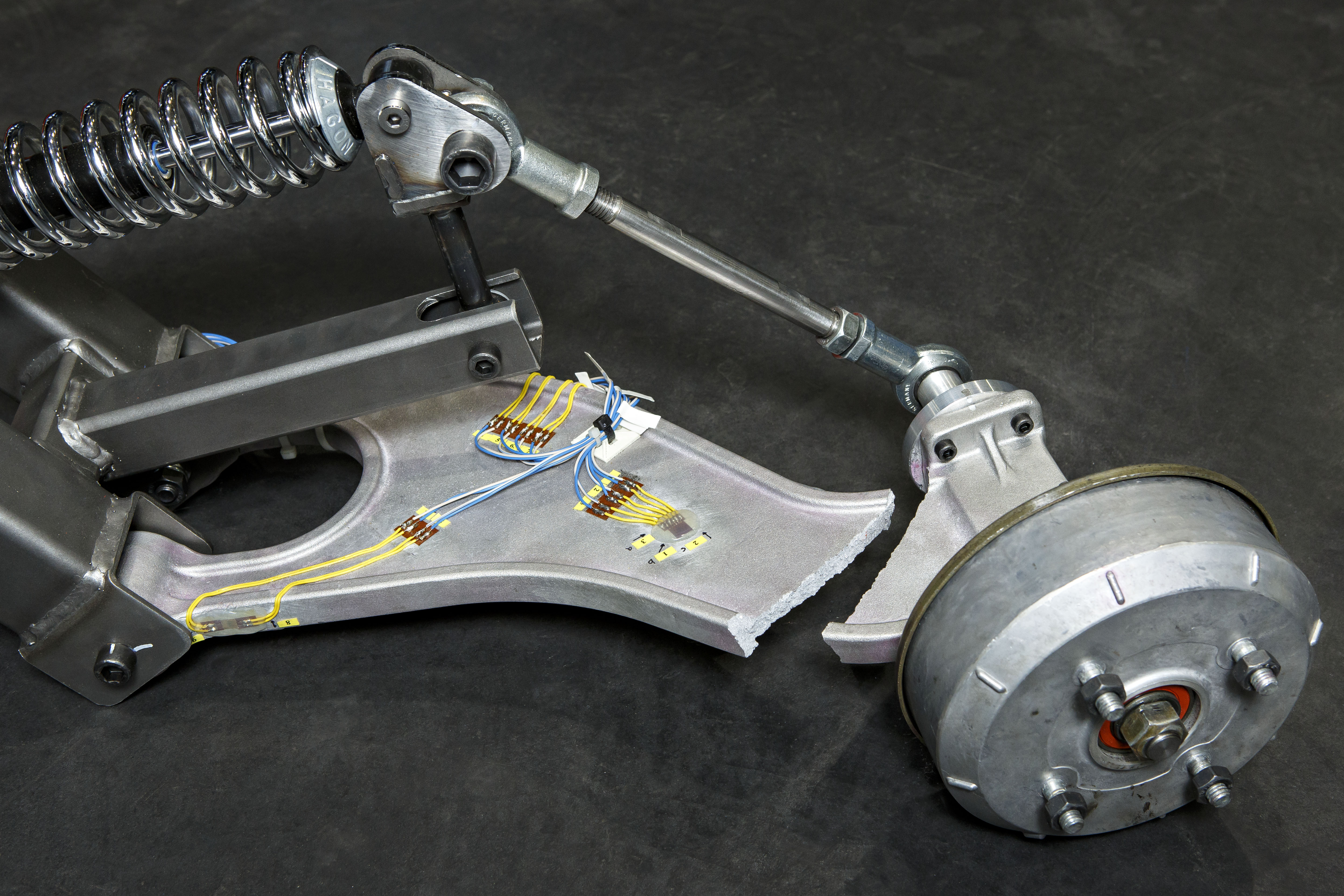

Based on experimental and numerical investigations of material and component vibration strength as well as fatigue analyses of transport and storage components, lifetime evaluations for critical components are carried out. Based on these analyses, optimization potentials for the component design of infrastructure elements, drive components or system elements of fuel cells (e.g. with regard to geometry, material thickness) are derived. These findings can in turn be used to increase the service life of the components and systems. Optimized component design will also enable the use of new (optimized) materials and components to increase the efficiency of fuel cells.

High Performance Center - Green Materials for Hydrogen, Hesse

High Performance Center - Green Materials for Hydrogen, Hesse